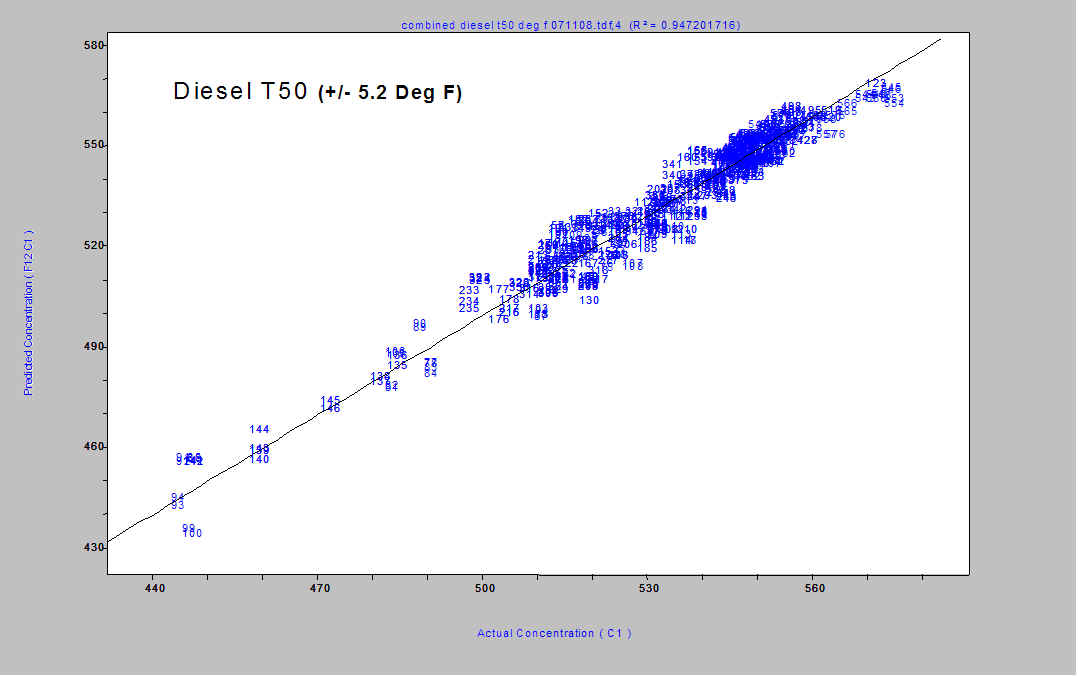

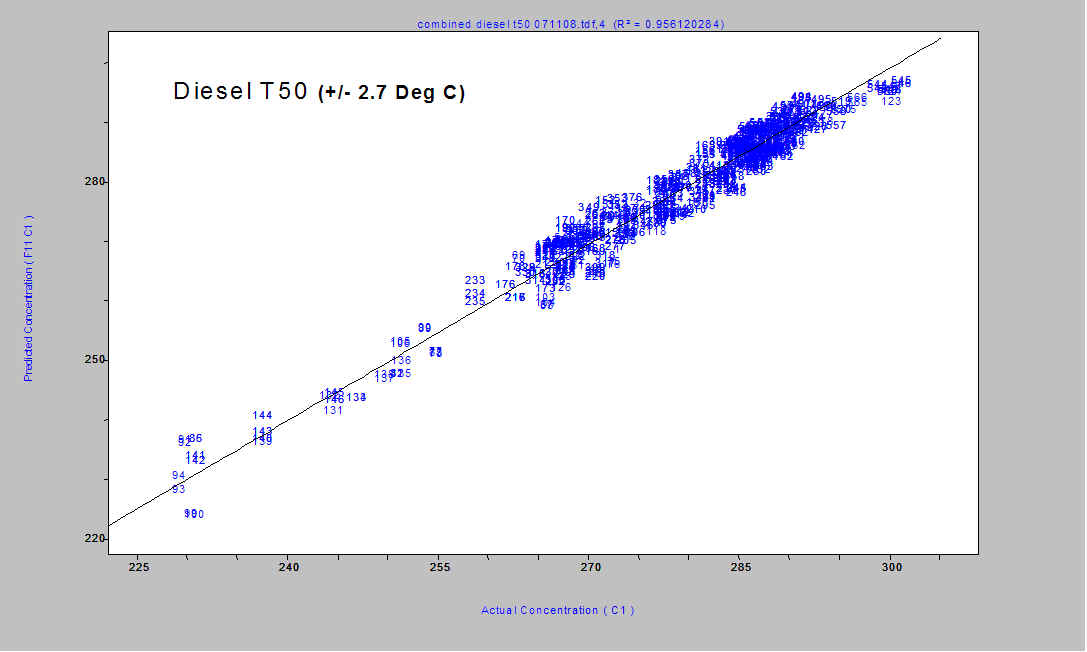

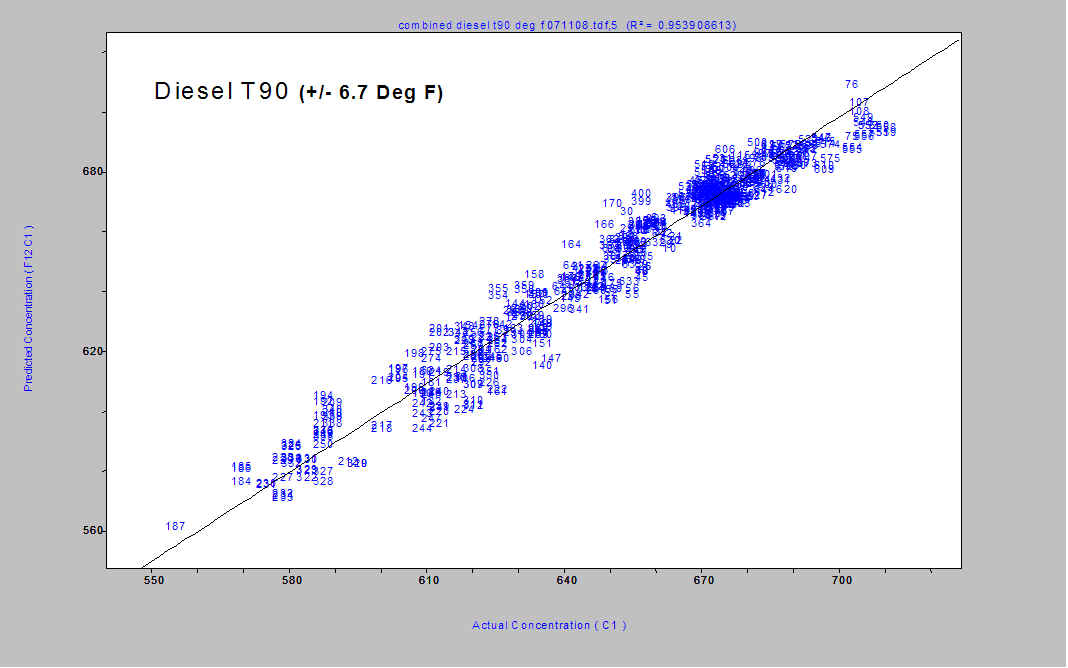

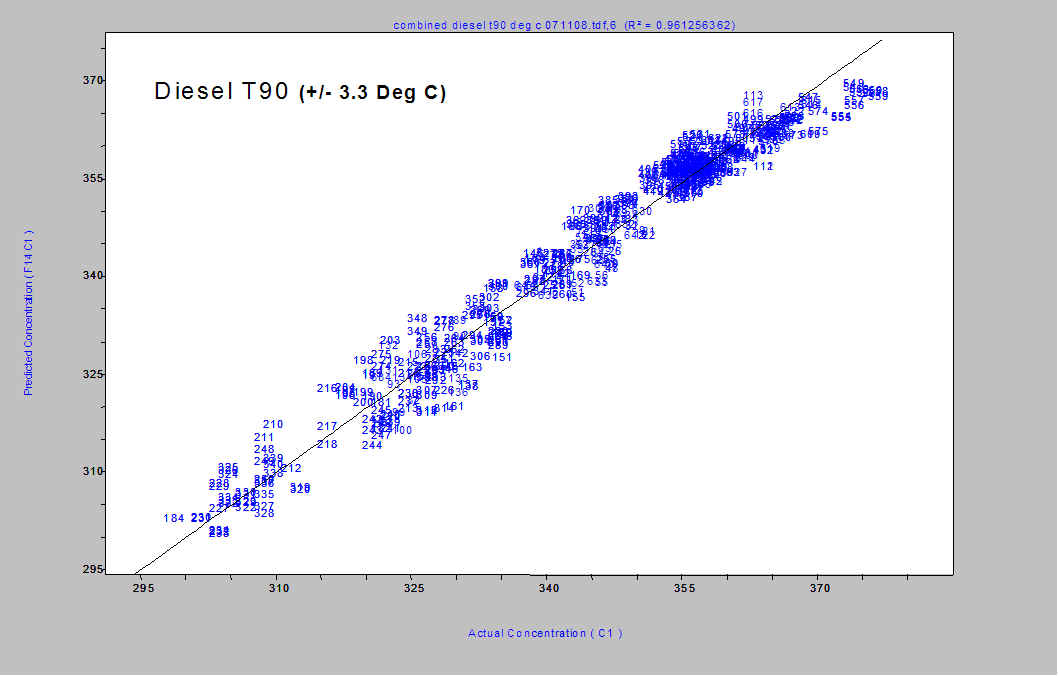

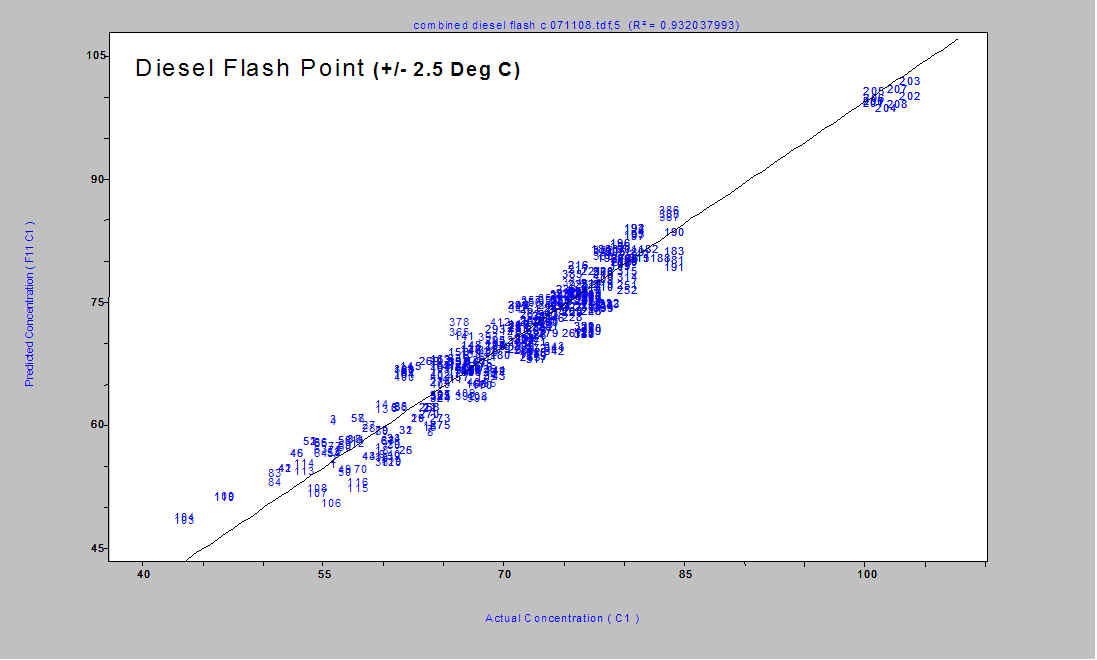

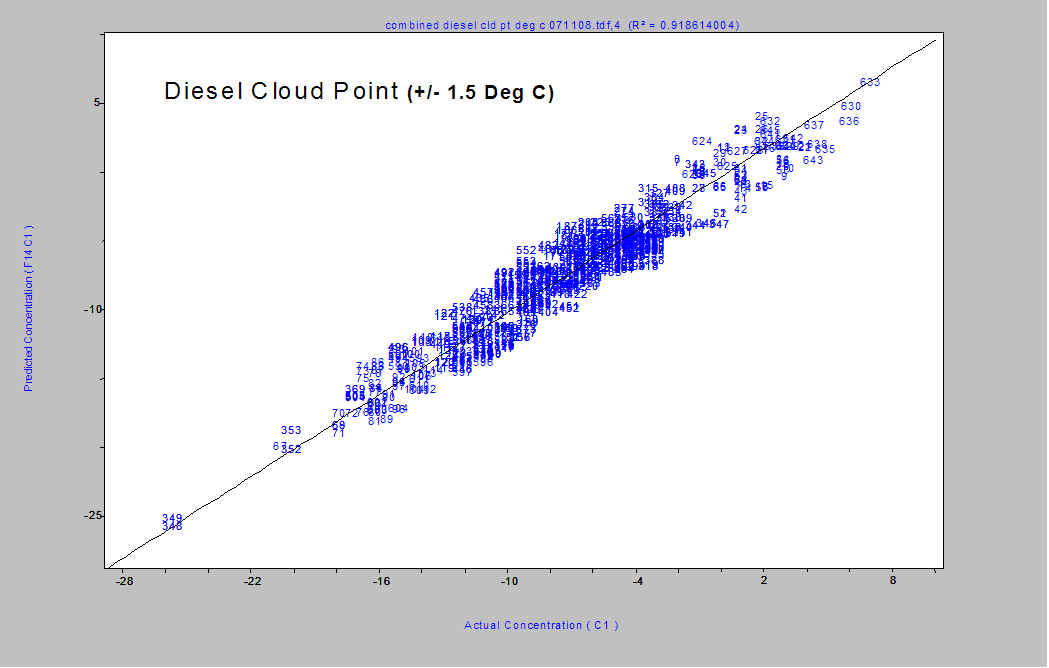

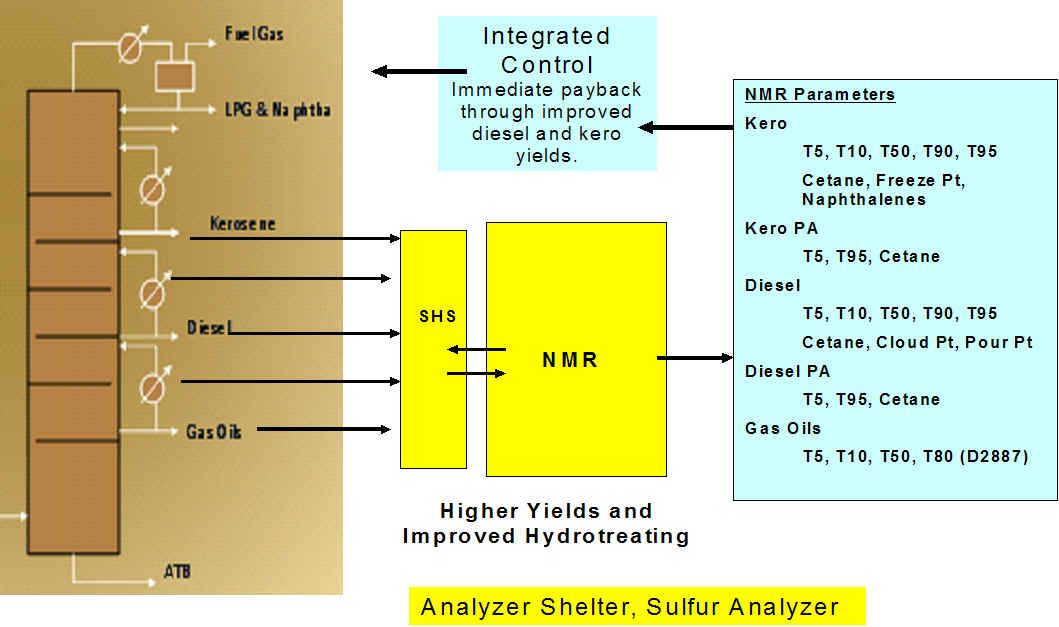

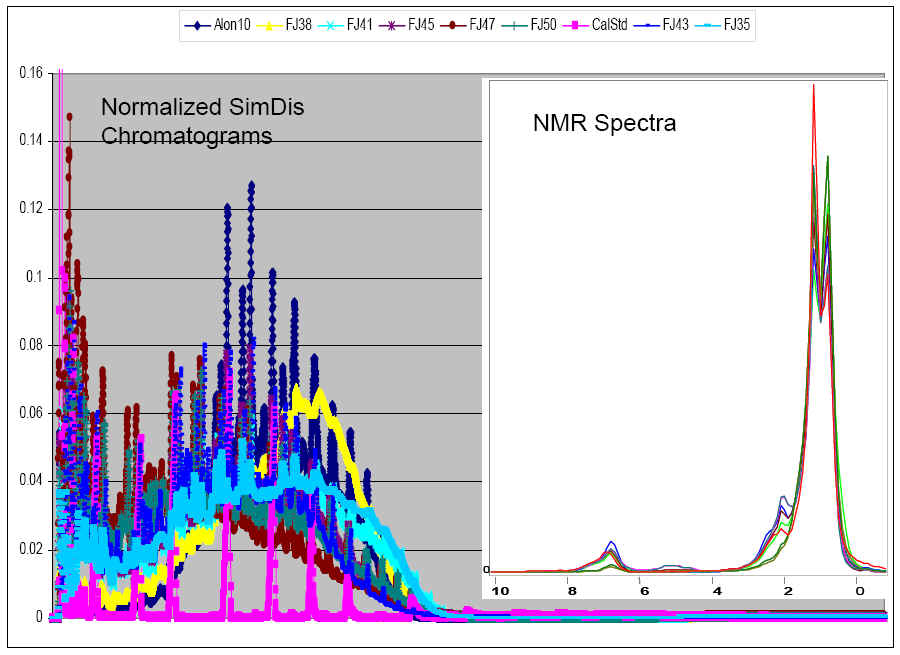

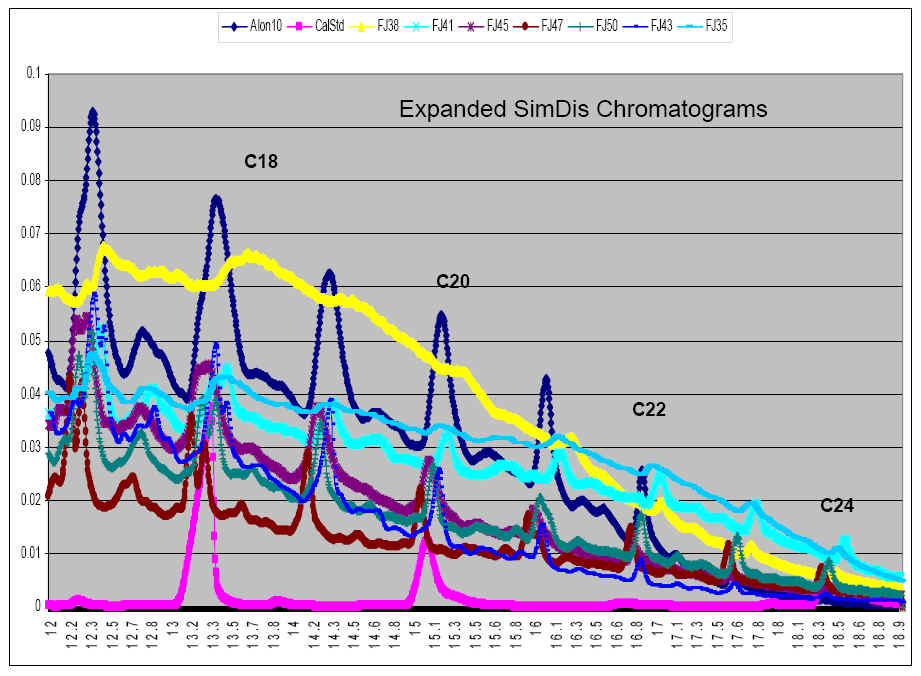

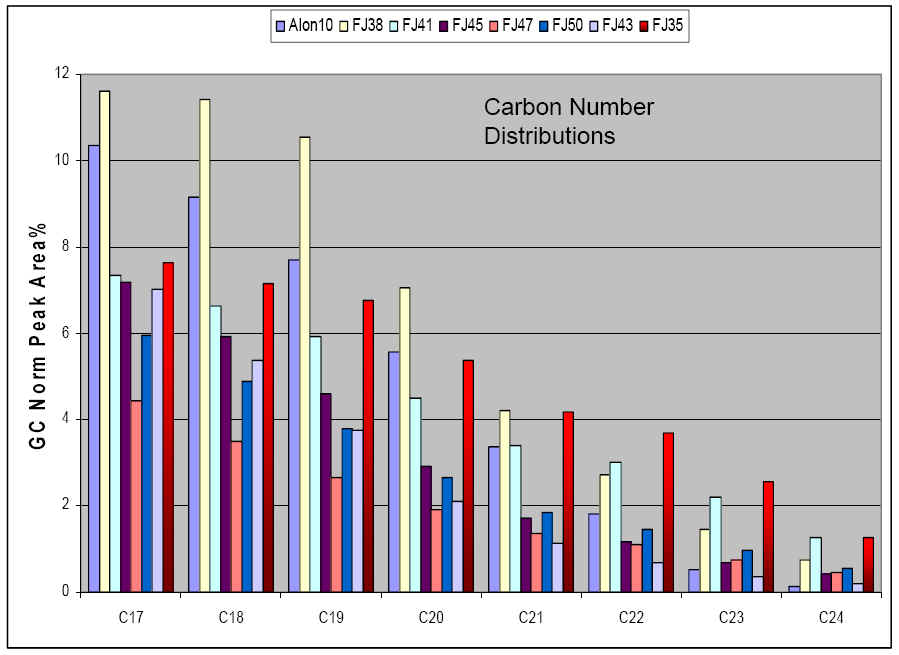

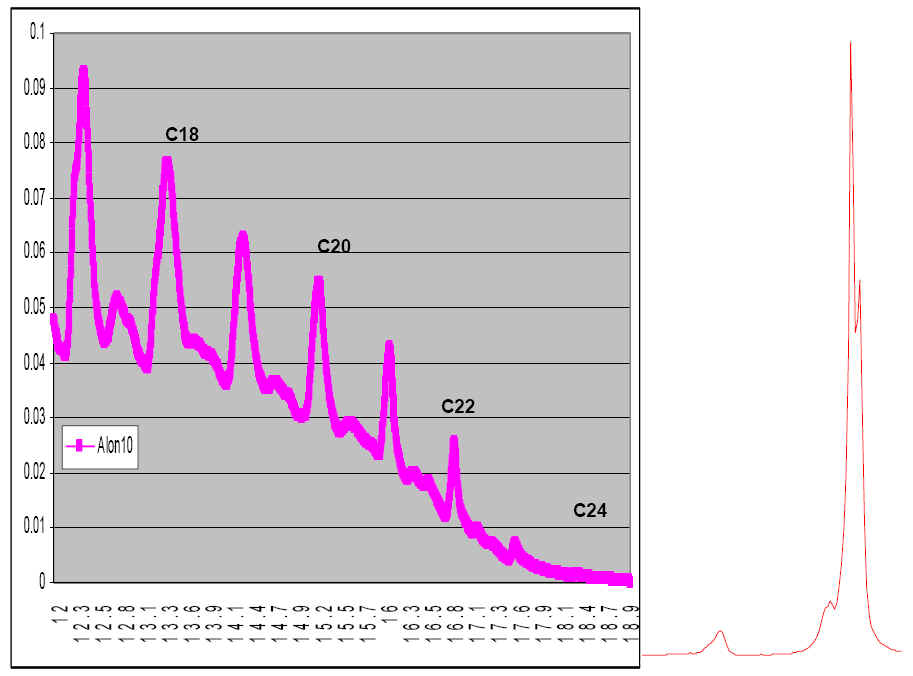

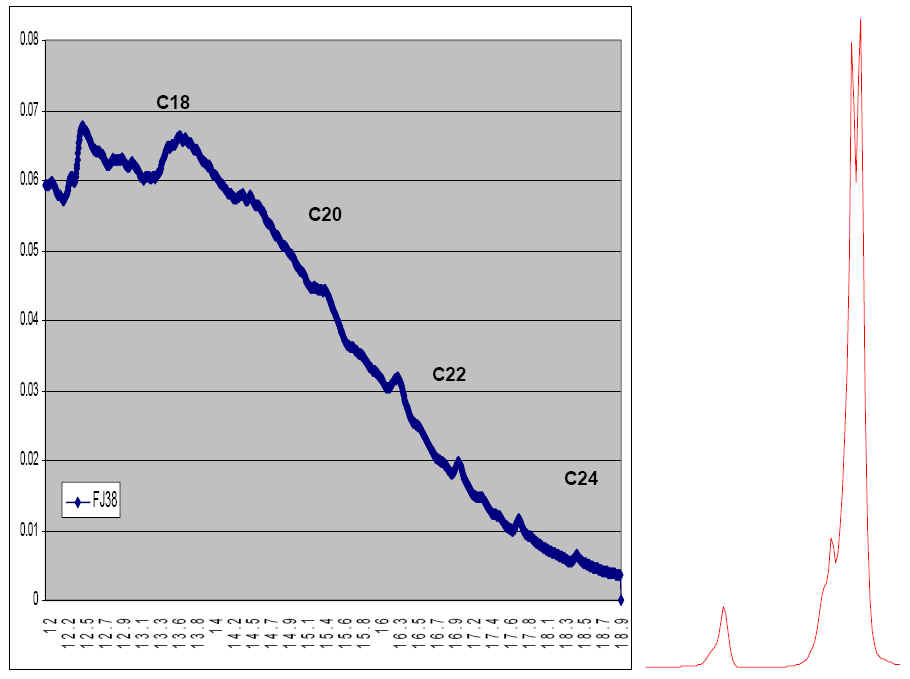

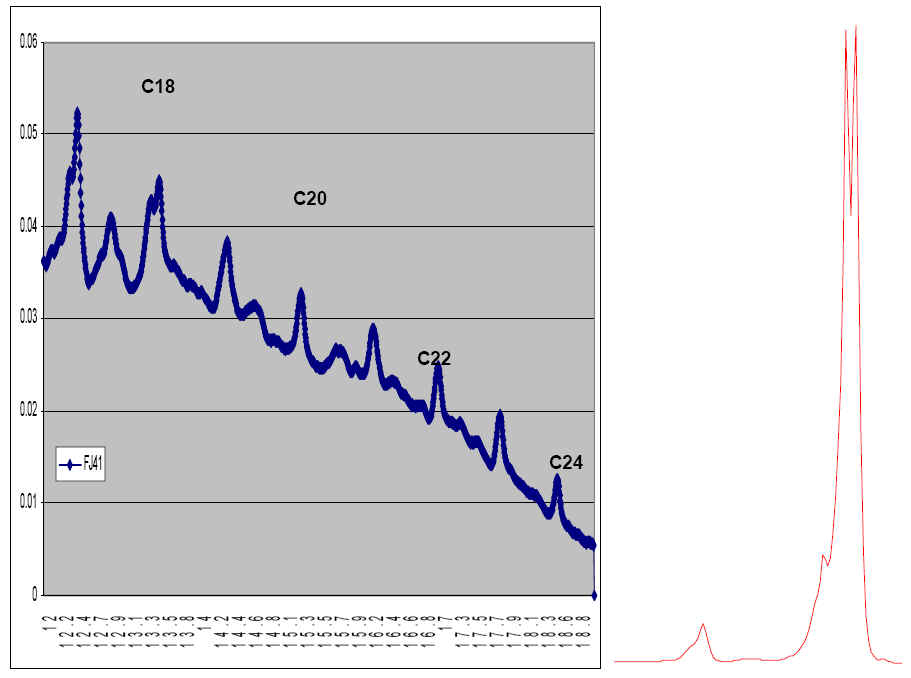

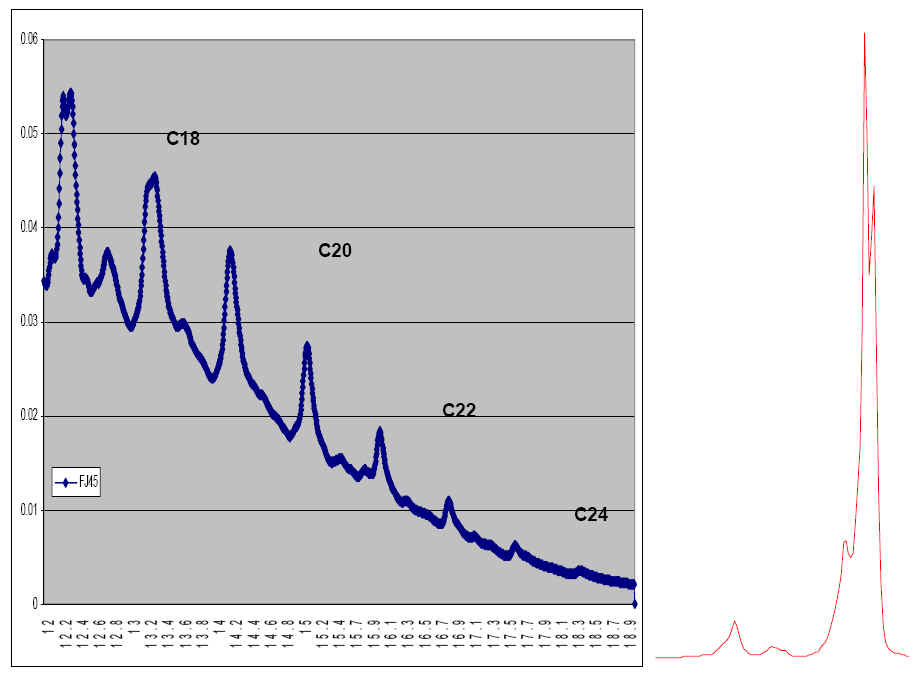

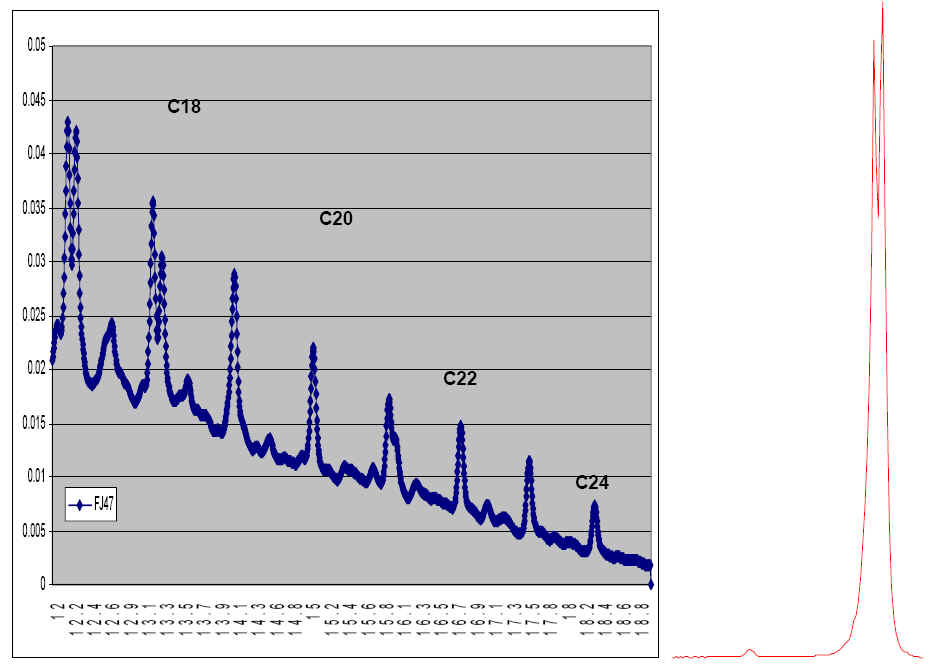

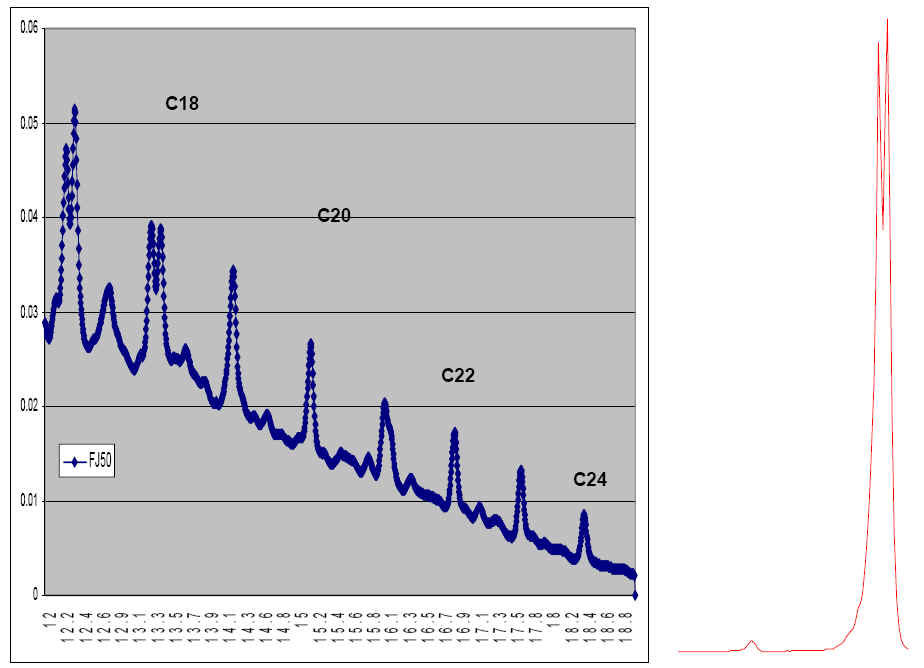

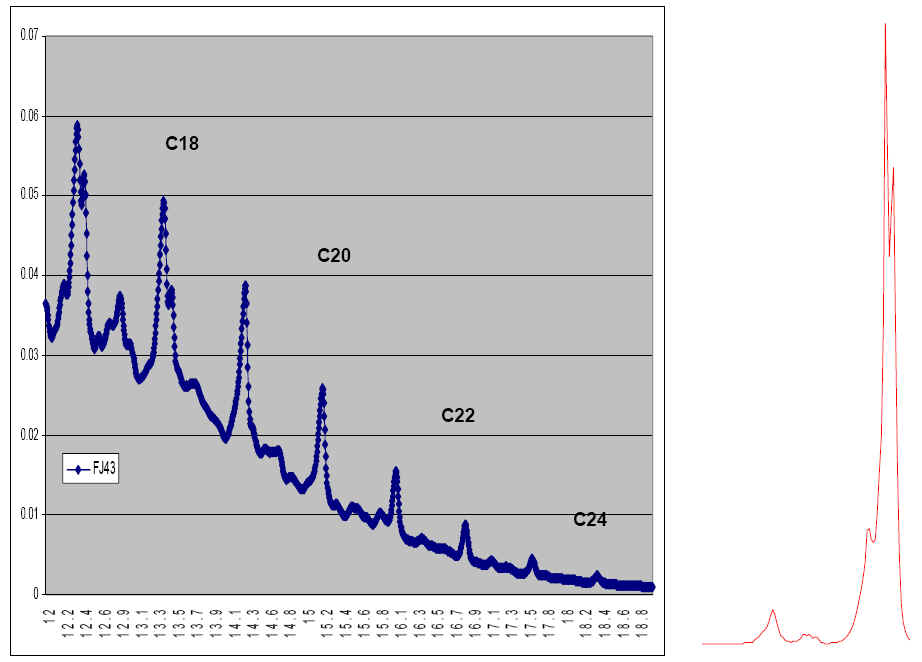

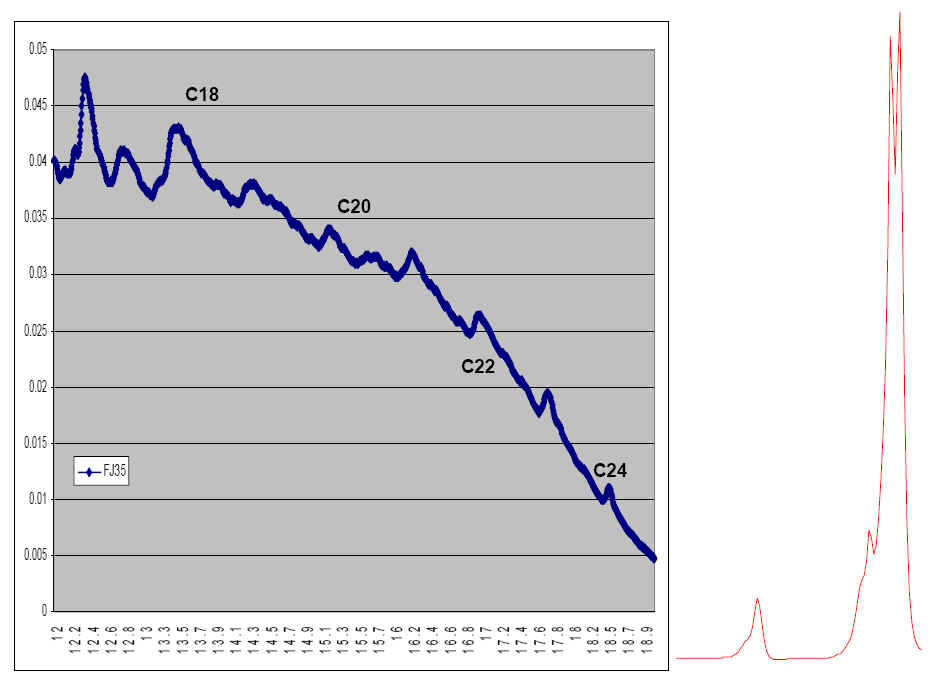

Process NMR Associates has developed a database of Simulated Distillation database on a large number of diesel fuels on our Shimadzu 2010-GC with SimDis Software. The analysis is being used to develop distillation prediction models for the process NMR systems as well as explore new avenues of control information that can be derived by combining carbon number distributions obtained from the GC data with the predictive capabilities of online NMR.

For a PDF version of this application article download this: Combination of NMR and Simulated Distillation for Diesel Production Control

Simulated distillation allows carbon number distributions to be calculated and in combination with chemistry observed in the NMR analysis the effect of aromatics and olefins on the paraffin distributios can be estimated. Online NMR predictions can be established that yield real-time carbon number distributions for production control and sulfur species monitoring.

Contact: Paul Giammatteo Tel: +1 (203) 744-5905