The use of an NMR as a simple flow detector for benchtop reaction monitoring, mixing monitoring, dilution monitoring, or conversion monitoring has been limited by the need to bring the

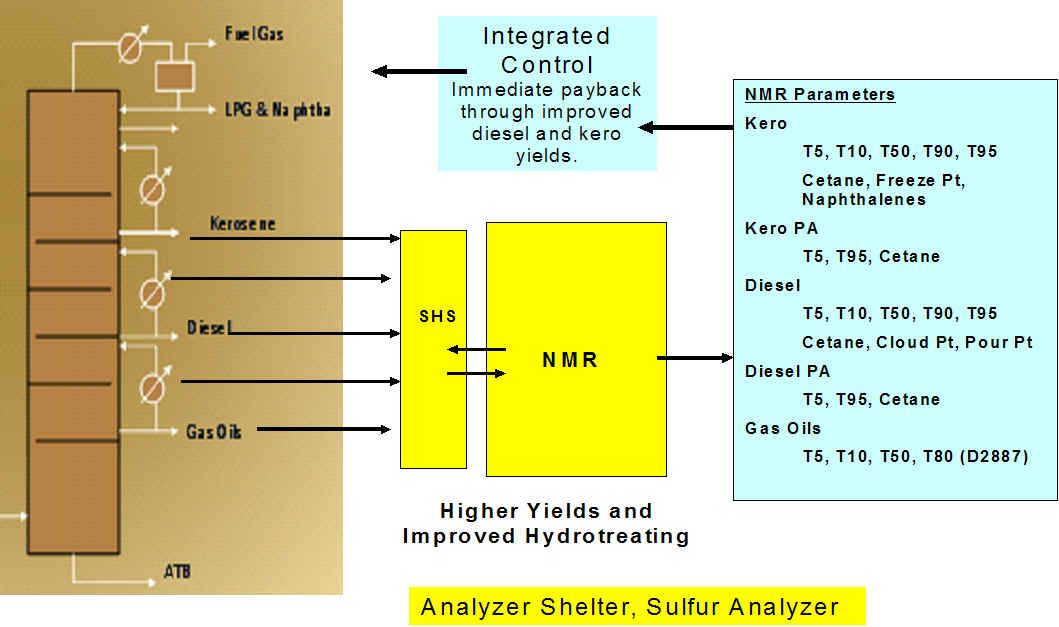

Diesel Production Control – Combination of NMR and Simulated Distillation to Yield On-Line Carbon Number Distributions

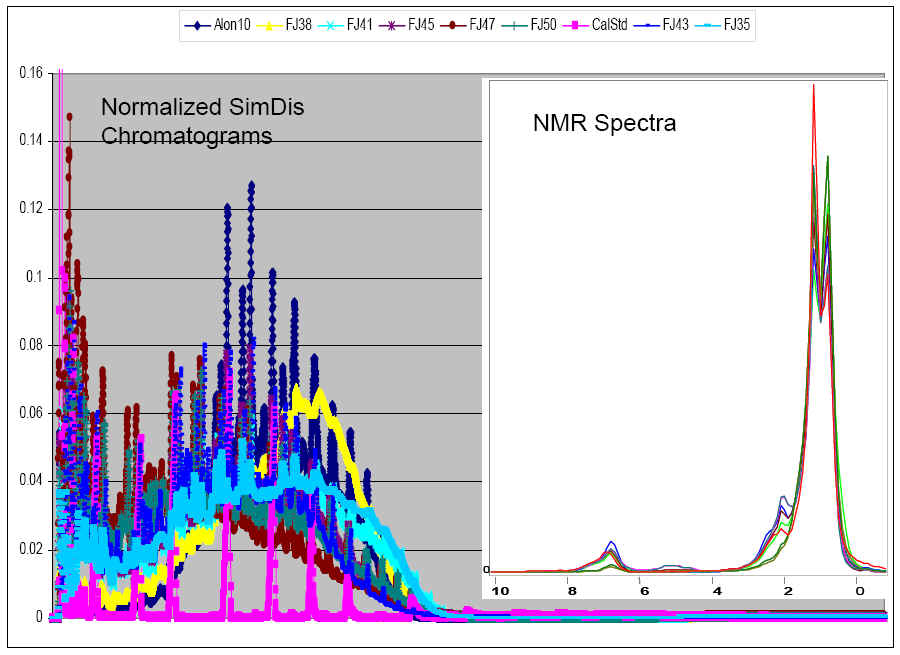

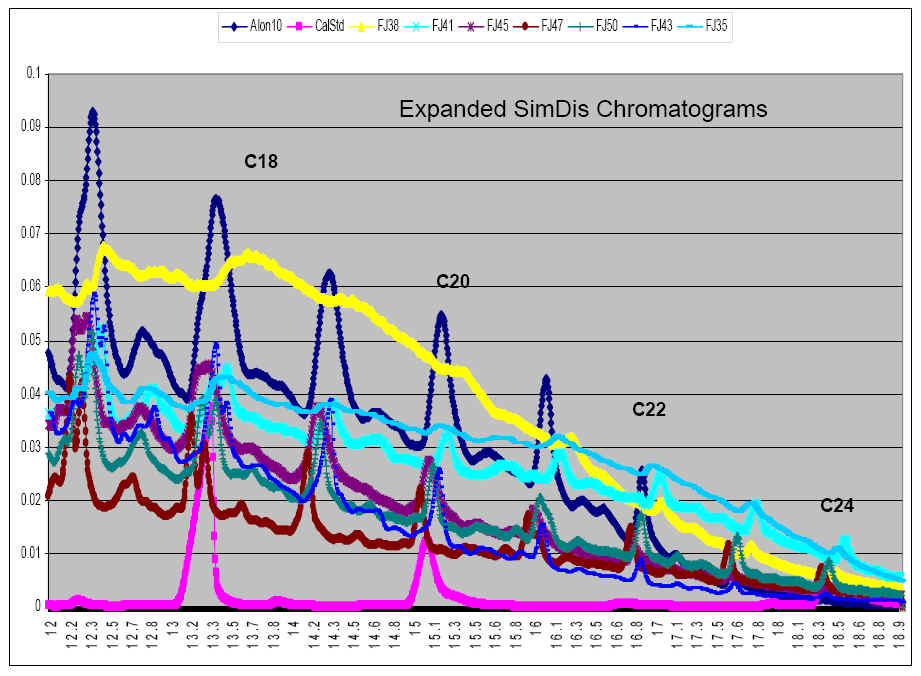

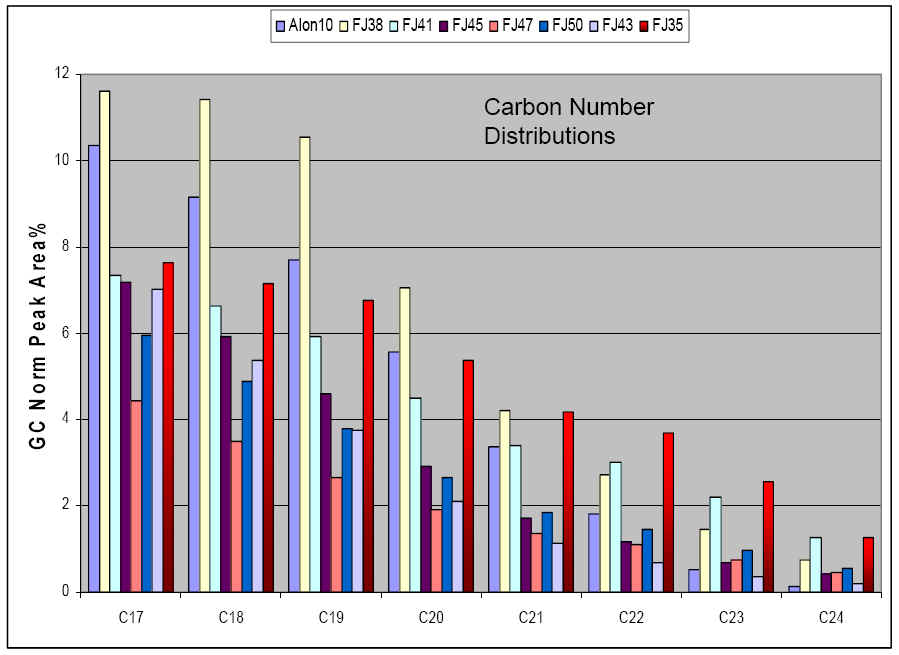

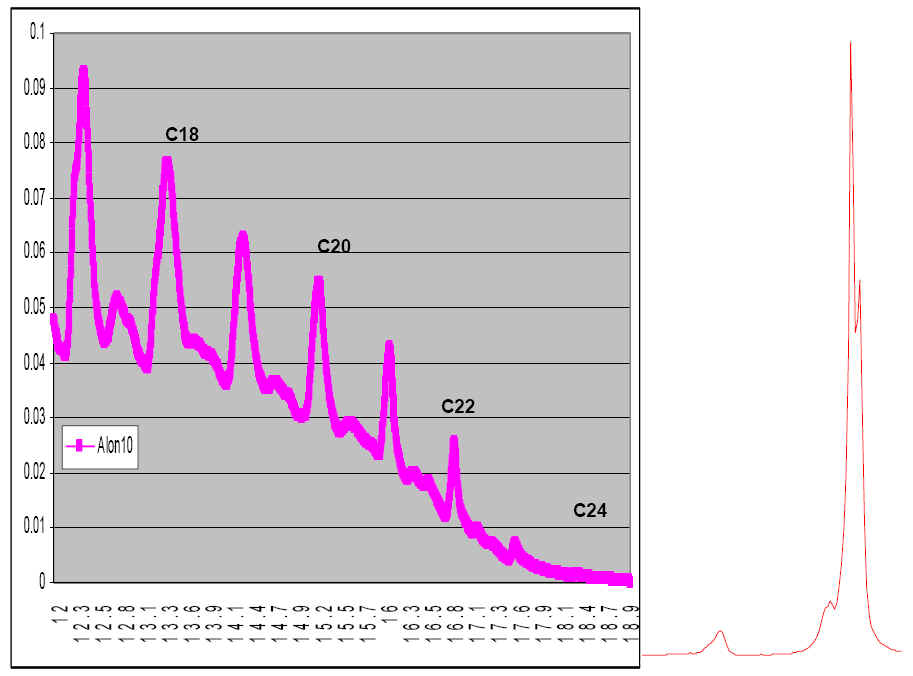

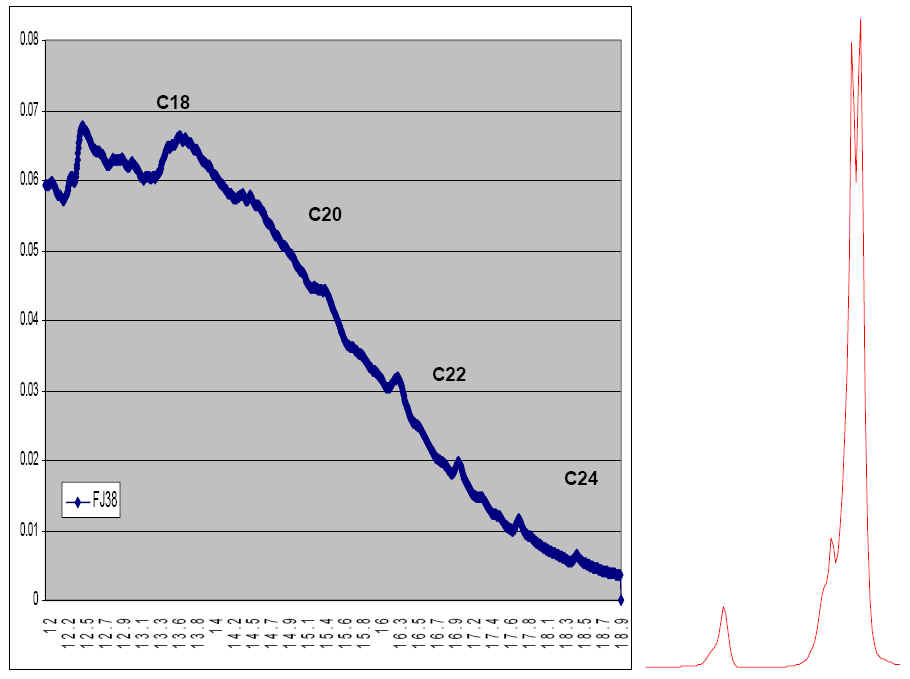

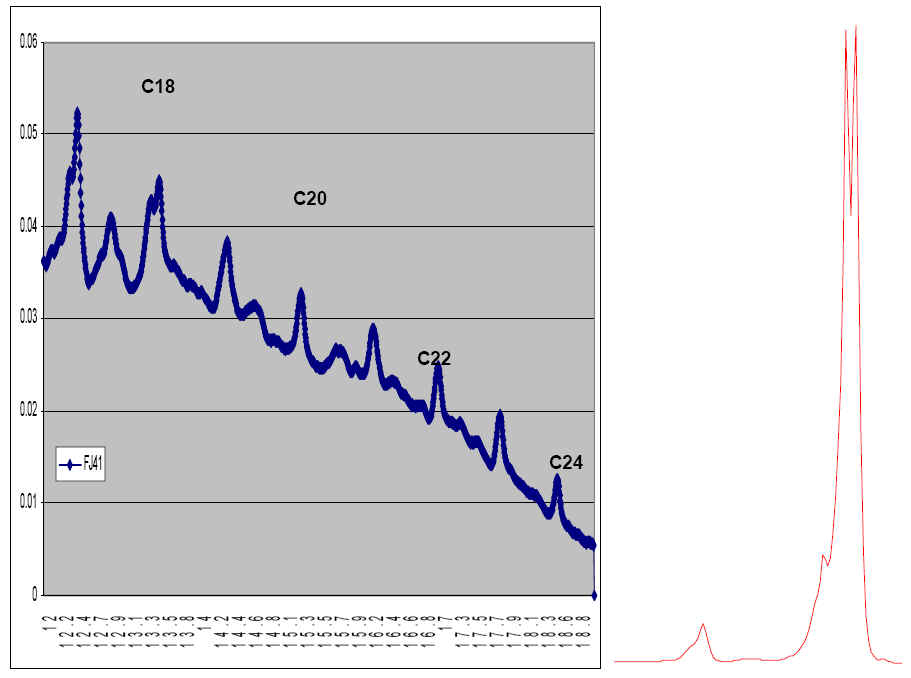

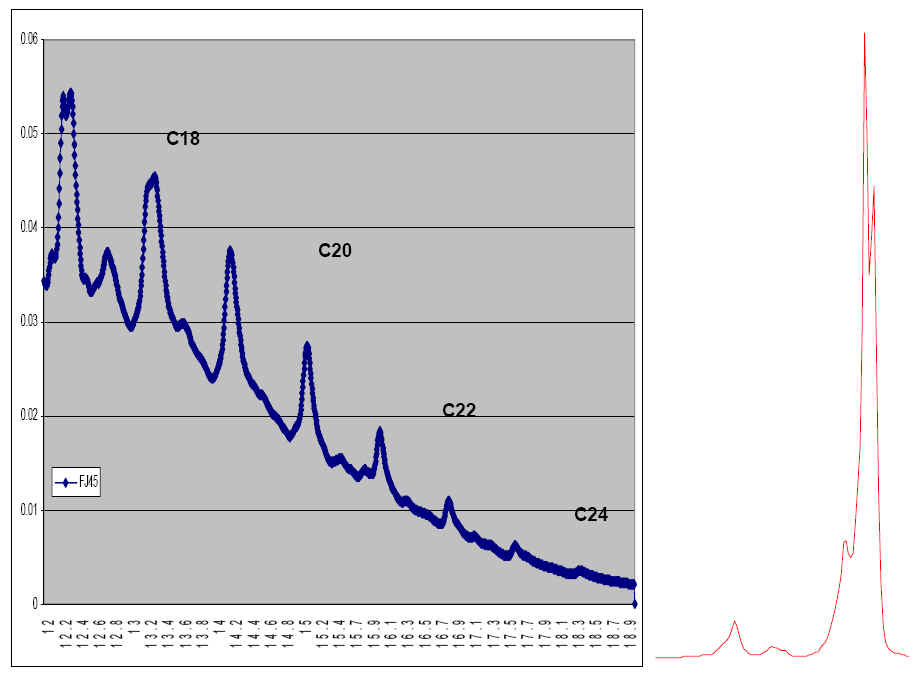

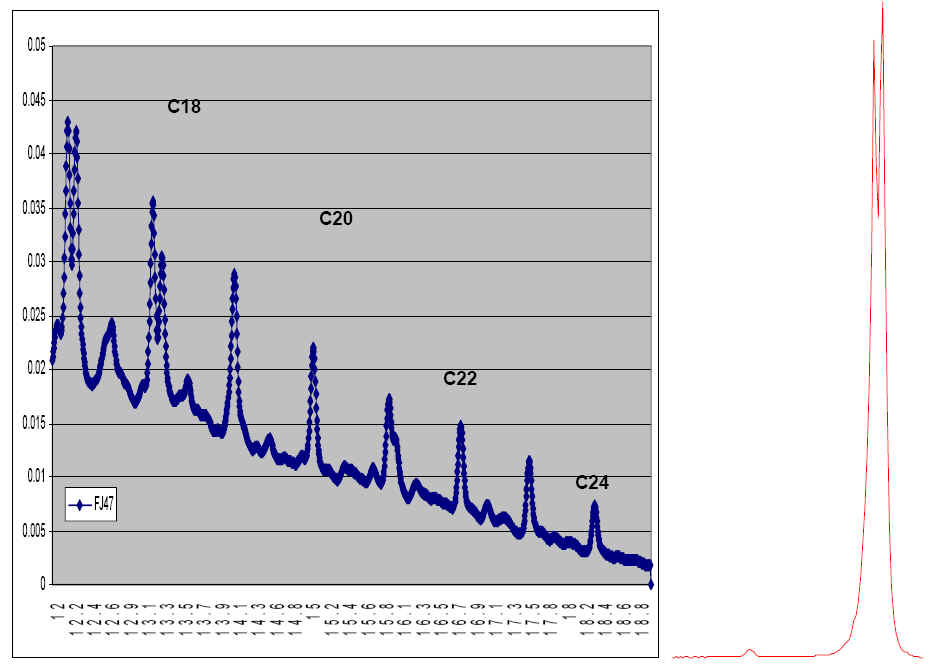

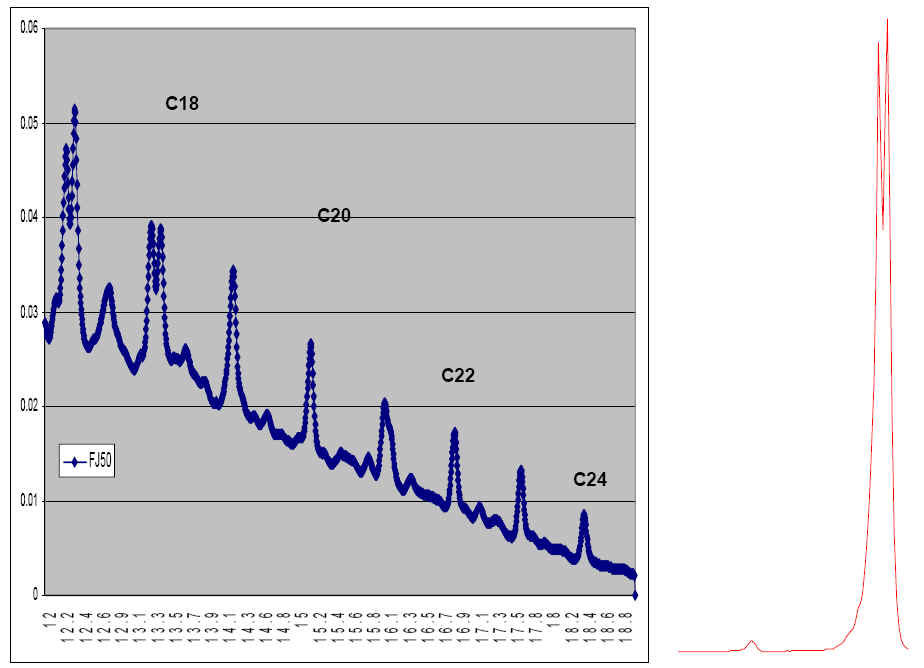

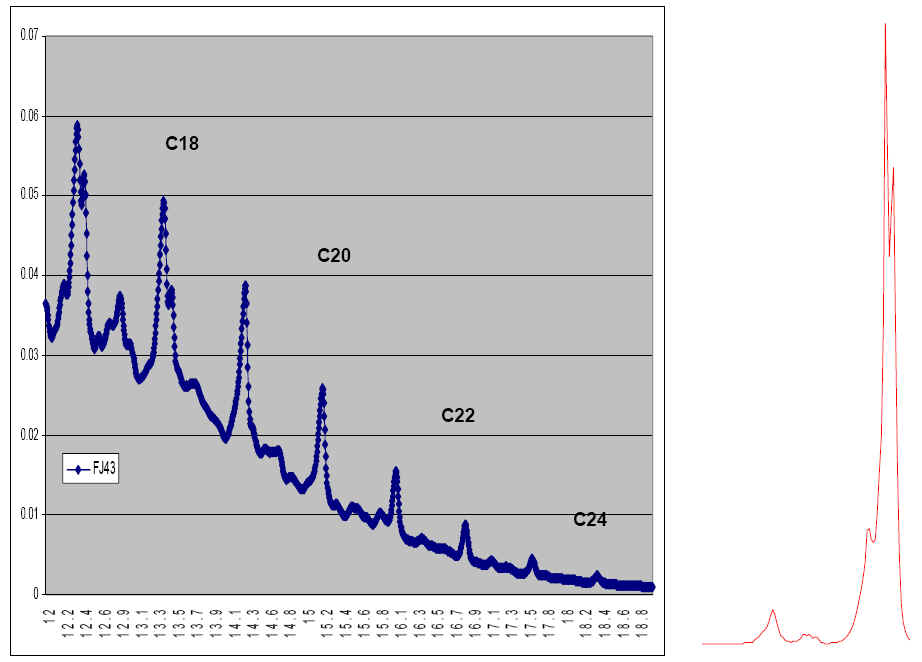

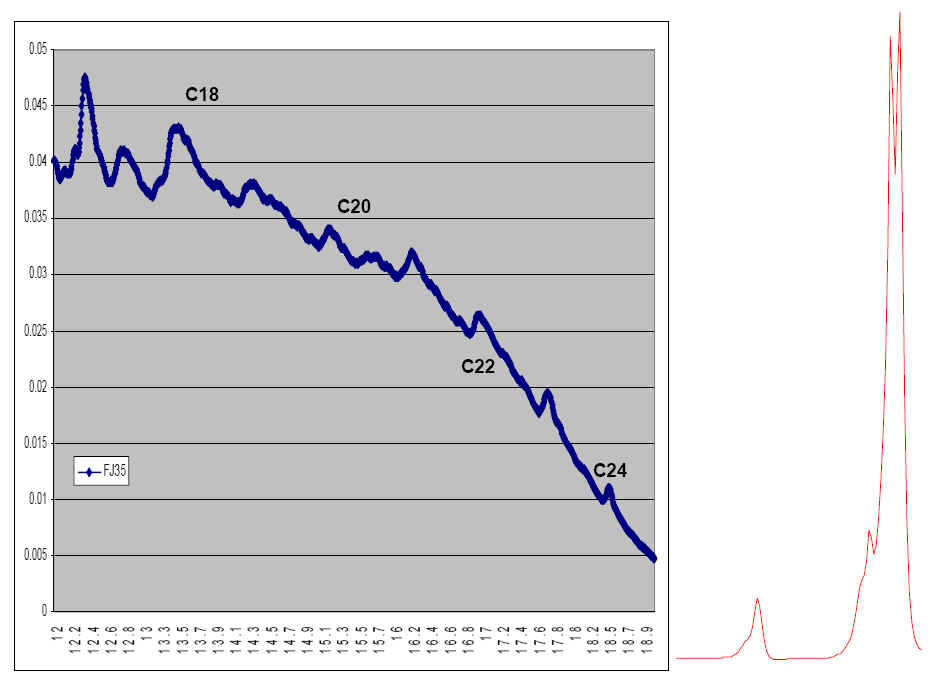

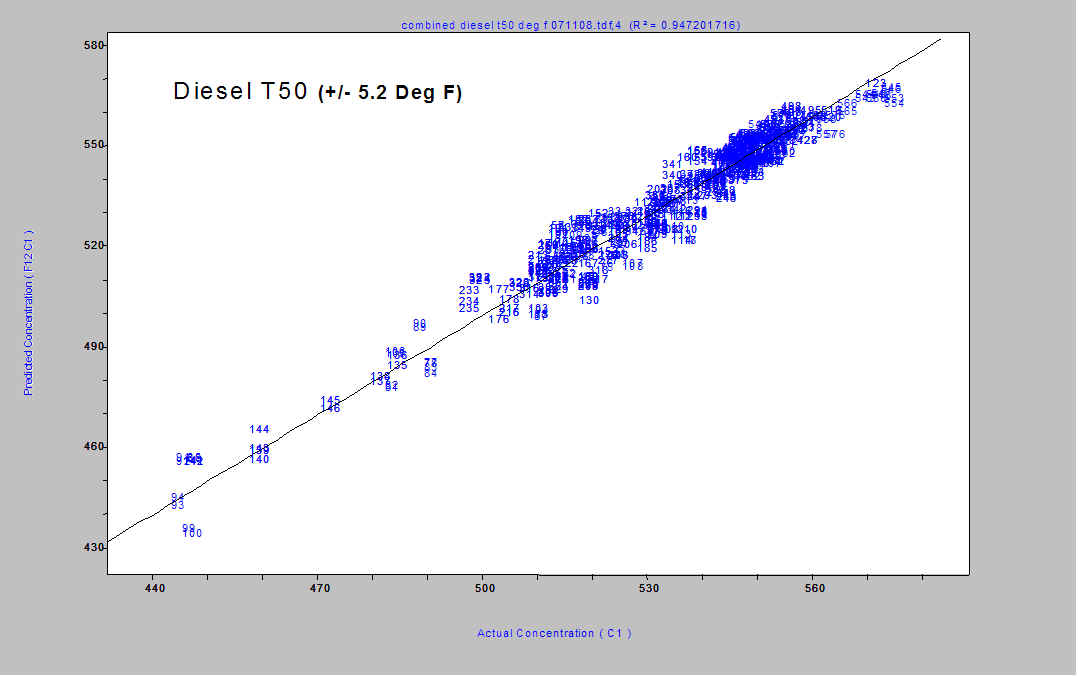

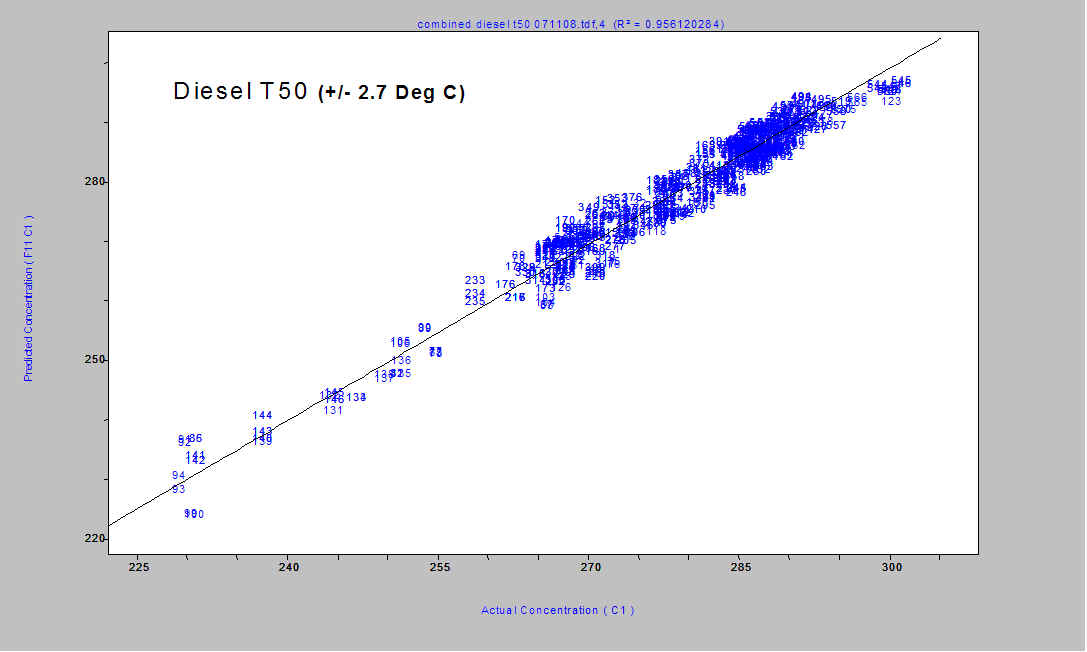

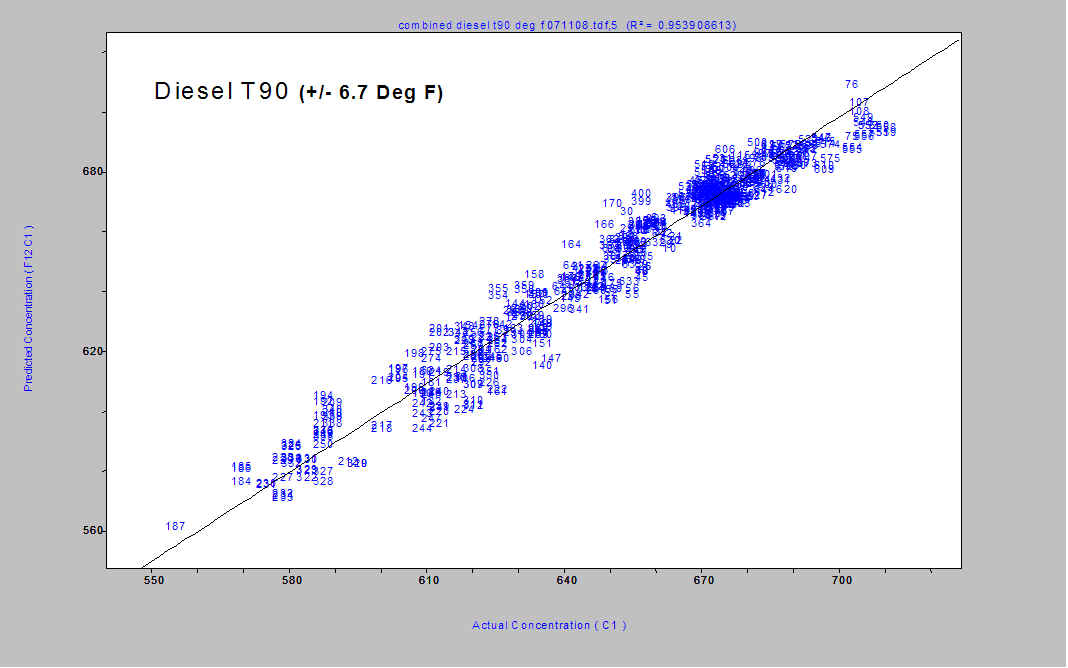

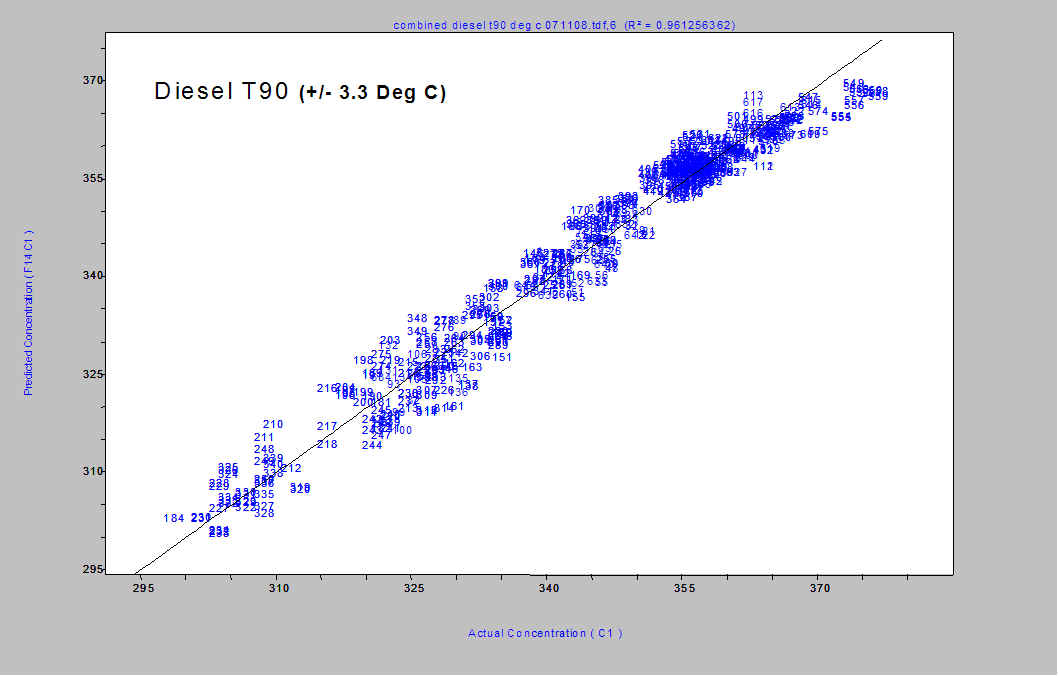

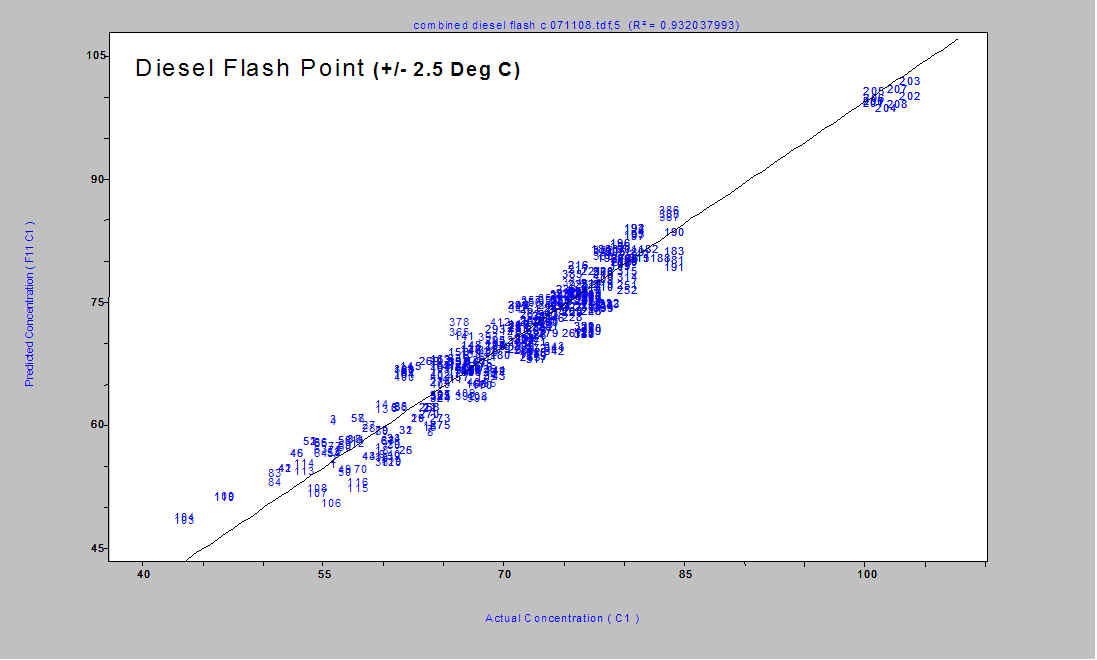

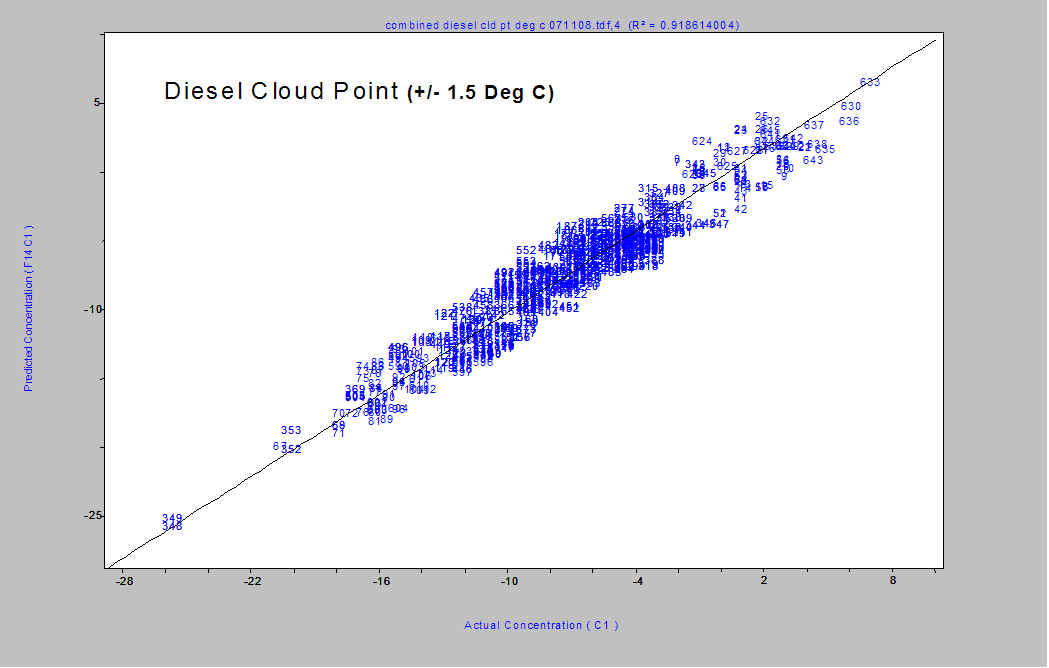

Process NMR Associates has developed a database of Simulated Distillation database on a large number of diesel fuels on our Shimadzu 2010-GC with SimDis Software. The analysis is being used to develop distillation prediction models for the process NMR systems as well as explore new avenues of control information that can be derived by combining carbon number distributions obtained from the GC data with the predictive capabilities of online NMR.

For a PDF version of this application article download this: Combination of NMR and Simulated Distillation for Diesel Production Control

Simulated distillation allows carbon number distributions to be calculated and in combination with chemistry observed in the NMR analysis the effect of aromatics and olefins on the paraffin distributios can be estimated. Online NMR predictions can be established that yield real-time carbon number distributions for production control and sulfur species monitoring.

Contact: Paul Giammatteo Tel: +1 (203) 744-5905

Extensive NMR Diesel Database Enhances NMR Model Performance for Unit Control and Product Manufacturing

An extensive database (10 years) of diesel samples incorporating all refining processes (distillation through product blending) enables development of robust, wide ranging property predictions independent of crude sources and refinery processing. Consistent attention to data integrity enables expanding model ranges well beyond any typical single unit or process operation. The following slides elucidate the consistency in spectra whether obtained 10 years ago or last week, from within a refinery or on a laboratory spectrometer.

If you are interested in finding out more about NMR and diesel production control contact Paul Giammatteo or phone him at +1 (203) 744-5905 – see the Process NMR Associates website for further information

Schering-Plough Corporation Seeks Process Analytical Technology Manager

Title:

Process Analytical Technology (PAT) Manager

Description:

Implement Process Analytical Technology (PAT) throughout all the Global Quality Sites to identification of incoming materials and monitor manufacturing processes.

Work directly with the sites and Schering Plough Research Institute to help support / initiate the development, validation, and deployment of PAT at the sites.

Review, evaluate, implement, and manage PAT activities.

Provide guidance / technical help to the sites to conduct evaluation and purchase commercial PAT related analytical equipment (e.g. NIR / FT-NIR, Raman / FT-Raman, IR / FT – IR etc.).

Maintain analytical instruments in the lab to comply with cGMP standards and requirements.

Train and mentor laboratory staff on PAT to generate analytical data for routine experiments.

Generate network and infrastructures with various sites of the corporation.

Take full ownership / responsibility and provide effective, meaningful, result driven and pro-active leadership on all PAT projects.

Responsible to transfer knowledge / technology of PAT related projects and activities to sites. Job is located in New Jersey.

Respectfully, Vincent L. Graziano

Recruiting Manager / Global Staffing

Schering-Plough Corporation

556 Morris Avenue, S1-1

Summit, N.J. 07901

Ph: 908-473-2745

Fx: 908-473-2793

Ph: 908-298-5232 (Kenilworth)

Careers: Employment Opportunities

email: vincent.graziano@spcorp.com

The Wood-Based Biorefinery in a Petroleum Depleted World

The Mid-Hudson Section of the American Chemical Society and Vassar College Announce

The Wood-Based Biorefinery in a Petroleum Depleted World

Dr. Arthur J. Stipanovic,

Professor and Chair, Department of Chemistry

State University of New York, College of Environmental Science and Forestry (SUNY-ESF)

Wednesday, November 7th, 2007

Time: 7:00 pm

Location: Mudd Chemistry Building, Third Floor

Refreshments will be served at 6:30 pm

Vassar College, Poughkeepsie, New York

Contact: Dr Joseph Tanski (jotanski@vassar.edu, 845-437-7503)

Abstract: The 21st century is envisioned to become the age of biology as renewable biomass resources replace petroleum in energy and industrial product applications. Motivated by concerns over national energy security, global CO2 reduction, a need for biodegradable products, and enhanced rural economic development, the engineering and construction of biorefineries for the manufacture of fuels, chemicals, polymeric materials and power from renewable resources is now a critical national priority. The context and intent of a biorefinery must be much more than simply replacing crude oil with renewable raw materials. A successful biorefinery must: 1) efficiently separate its raw material source into individual components, and, 2) be able to convert these components into marketplace products. The biorefinery must mirror the efficiency of today’s modern petrochemical refinery in using all components of its raw material source for the production of chemicals, fuels, and power.

Woody lignocellulosic biomass is a complex, composite material consisting of three polymers in close association: hemicellulose, cellulose, and lignin plus small amounts of low molecular weight extractives and inorganics. In this presentation, a group of synergistic biomass feedstock and biorefining technologies under development at SUNY-ESF, in collaboration with many industrial and academic partners, will be discussed including: short-rotation fast growing willow production, biodelignification, hemicellulose extraction, polymer conversion to fermentable sugars, biodegradable thermoplastics and hemicellulose-based composites.

See the Stipanovic Website at SUNY_ESF for further details…..http://www.esf.edu/chemistry/faculty/stipanov.htm

Bio: Dr. Arthur J. Stipanovic is currently Professor and Chair of the Department of Chemistry at the SUNY College of Environmental Science and Forestry (SUNY-ESF) in Syracuse , NY , and also serves as Director, Analytical and Technical Services. His research interests include biodegradable polymers from renewable resources, high-throughput analytical techniques for determining the composition of woody biomass and new processes for the wood-based biorefinery. Dr. Stipanovic received both his B.S. and Ph.D. degrees from SUNY-ESF in polymer chemistry and much of his career was spent at the Texaco R&D labs in Beacon, NY, in new technology and lubricants research. He is a past Councilor and Executive Board member of the Mid-Hudson ACS section and, more recently, has served as Chair of the Syracuse section.

Directions: Vassar College is located off Raymond Avenue in Poughkeepsie , NY. Refer to the following link for driving directions and campus map: http://www.vassar.edu/directions/. Enter the Main Entrance of the campus on Raymond Avenue and go right towards the Mudd Chemistry Building. The Security Guard at the Main Entrance will direct you to parking.