NMR Process Systems – Integrated Solution – Crude Unit and Downstream Processes

Spectro-Molecular Control – Enhanced Diesel Recovery [PDF Version]

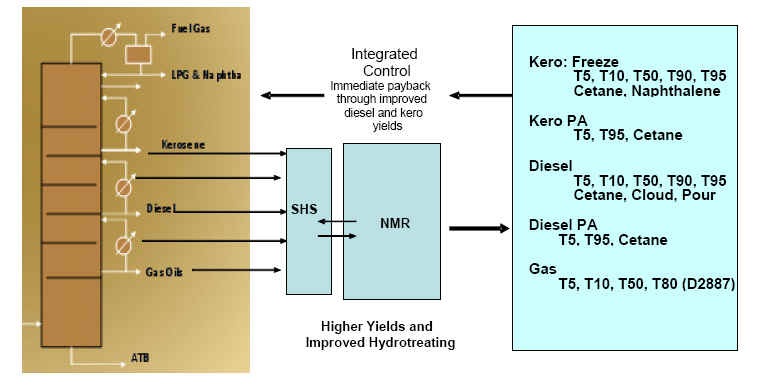

NMR Process Systems’ (NPS) on-line NMR based analytical and process control strategy for enhanced diesel recovery at the crude distillation unit maximizes clean diesel recovery by enabling closer cut point control in the mid-section of the CDU.

Clean Fuels regulations in both the European and American markets have had a substantial impact on a refiner’s ability to maximize product draws at the refinery front end. Extremely low sulfur requirements for gasoline and diesel have resulted in refiners now being more constrained at the hydrotreaters. Lack of reliable, focused, measurement and control of critical CDU product draws has forced many refiners to significantly undercut these draws in order to ensure minimum error in the final product blends, especially with respect to total sulfur. Depending on a refinery’s crude supply and CDU capacity, a conservative estimate of 300-500+ barrels per day of loss diesel production is typical. With an average of $25 – $35 per barrel margin loss, the economic impact of these Clean Fuels Regulations are substantial.

Integrating proven NMR technology with a focused measurement and control strategy enables crude unit operations to cut “chemically” closer to the hydrotreater constraint limit. The strength of NMR is that it quantitatively and accurately “observes” the chemistry of each refinery stream and readily relates that chemistry to chemically dependent parameters such as distillation, cetane, freeze points, etc. The NPS strategy is to cut and control CDU diesel production as closely to the dibenzothiophene distillation limit as possible.

Figure 1 illustrates this strategy in terms of both current and proposed NMR based measurements.

Let NMR Process Systems deliver “Spectro-Molecular” Control to your refinery so that you can achieve real economic and production benefits.